An In-Depth Look at the Physical and Chemical Structure of Cotton and Its Commercial Varieties

Physical and Chemical structure of Cotton

Physical structure

Each cotton fiber composed different layers, cuticle, primary wall, secondary wall and a lumen.

Cuticle:

The cuticle is the outside layer or the skin of the cotton fiber, which contain some cellulose but accompanied by fat and waxes. The waxes component of the cuticle enables it to adhere tenaciously to the primary wall of the fiber.

Primary wall:

Beneath the cuticle is the primary cell well composed of crisscrossed fibrils of cellulose and containing some pectins. The crisscross pattern of the fibrils confers peripherical strength of the fiber.

Secondary wall:

The secondary wall constitutes the bulk of the cellulosic component, which lies between the primary wall and the lumen of the fiber. The secondary wall of a matured fiber is practically pure cellulose and probably represents about 90% of the fiber weight. It is composed of two layers S1 and S2 with a thickness of about 100nm.The fibrils of the secondary wall are about 10nm thick that aligned parallel and packed densely running lengthwise throughout the fiber with spiral winding of 25-35 to the fiber axis.

Lumen:

The lumen, the innermost part of the cotton fiber, is a hollow canal running the length of the fiber. It has proteins, coloring matter and minerals deposited on its walls.

Before ball opening, the lumen is filled with liquid containing the cell, nucleus and protoplasm. The twists and the convolutions of the dried fiber are due to the removal of this liquid. Depending on the maturity of the fiber, the lumen varies in dimensions over a wide range. Mature fiber may have so heavy deposition of cellulose in the secondary wall which result is developing the fiber so fully as to leave a very little lumen at all. On the other hand, an immature fiber may contain so little secondary cellulose that the lumen is wide and distinct.

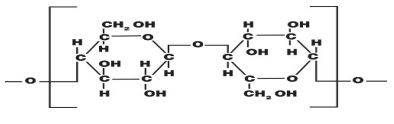

Chemical structure

Cotton is the most pure from the cellulose, so that chemical structure of cotton is characterized by cellulose structure.

Types of Commercial Cotton

Sea Island cotton:

This is the highest quality and the most valuable of all the commercial cotton. It grows on the coast of the golf of Florida in Barbados and in other adjacent islands where the climate is favorable.

Properties:

Length: Average length 2 inch

Diameter: Average 1/1500 inch (0.017mm)

Color: White to cream

Advantages/uses:

It is famous for its uniformity, maturity, high luster, softness and its highly developed twist. It can be used for spinning counts as high as 1/200.

Egyptian cotton:

There are two kinds of Egyptian cotton, one brown and the others white. Brown Egyptian cotton is like Sea Island cotton.

Properties:

Length: 1.5 to 1.75 inch

Diameter: Average 1/1500 inch (0.017mm)

Color: Brown, which makes the bleaching process more difficult

White Egyptian cotton is not so fine, having a staple length of about 1 inch.

Advantages/uses:

Brown Egyptian cotton is very regular and contains few immature or dead fibers. It can be used for spinning counts as high as 1/200. But white Egyptian cotton is not suitable for counts higher than 1/70.

South American cotton:

Length: Average length 1 to 1.5 inch.

It is very suitable for mixing with regenerated man-made fiber.

American cotton:

This is the cultivated in United States.

Properties:

Length: Average length 1 to 1.25 inch

Diameter: Average 1/1200 inch (0.021mm)

Color: good natural color

It cannot be used for the extremely fine count.

Indian cotton:

This is a short fiber of between 0.6 to 0.8 inch lengths. It is therefore only suitable for spinning coarse counts.

China cotton:

This is the lowest grade commercial cotton. The fiber length lies between 0.5 to 0.7 inch. Its twist is not highly developed and rather harsh. It is not suitable for spinning a good yarn alone and is usually used in mixer with better qualities.

Bangladeshi cotton:

Mainly American cotton is producing in Bangladesh. Commercial hybrid types cotton is producing at Maherpur, Kusthia, Jossore, Gazipur, Thakurgaon, Rajshahi and some other districts. The quality of Bangladeshi cotton is not suitable for quality textile processing. But their quality is improving day by day. During the year 2002/03 Bangladesh produced around 15000 MT cotton. It is possible to produce max. 60s Ne yarn from best quality Bangladeshi cotton.